As the integration of robotic welding continues to increase in most manufacturing operations, we often hear some of the same questions. In this video and transcript, our welding experts answer the top questions we hear when switching an operation to robotic welding automation.

Topics: Robotic Welding

1000th Production Robotic Welding System Delivered to East Manufacturing

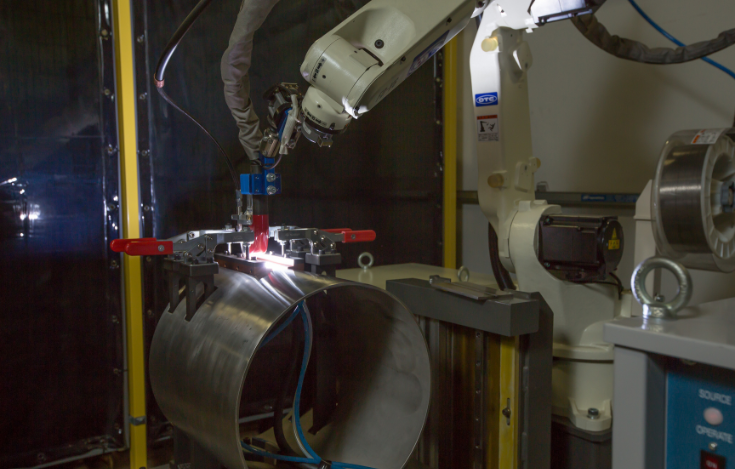

OTC DAIHEN and distributor partner Airgas are proud to have delivered the 1000th production robotic welding system — a SERVO-ARC 720B turntable robot welder – to East Manufacturing.

Topics: Robotic Welding, OTC DAIHEN News

New Technology Resolves Problems With Robotic Welding Aluminum and High-Tensile Steel

In response to the global trend toward carbon neutrality, materials are being shifted to high-tensile materials that are thinner and stronger and aluminum that is lightweight for weight reduction in products.

However, there is one common problem when using high-tensile materials or aluminum, it becomes difficult to weld joint shapes because of the variation in the joint gap.

To solve this challenge, OTC DAIHEN has evolved its exclusive robotic welding technology, creating Synchro Feed Evolution with Push Arc welding mode.

Topics: Robotic Welding

How to Integrate Welding Robots in Automotive Manufacturing for Maximum Results

Meeting today’s demand for vehicles that are more lightweight, affordable and safer means automotive manufacturers are faced with new challenges, such as creating strong welds on thin materials and adapting more efficient processes for faster cycle times.

These challenges have led to increased growth in the integration of welding robots into the automotive manufacturing process. When integrating a welding robot – whether it’s a new robot on the line or an upgrade of an existing robot – take these steps to help uncover how to work with existing capital equipment to gain maximum results and optimal ROI.

Topics: Robotic Welding

Retrofitting a Robot Welder for Higher Production While Saving Time & Costs

The concept of retrofitting current robotic systems has taken on greater popularity in the last year as manufacturers seek more affordable and faster options to help maintain a competitive advantage in demanding markets.

This is especially true with welding robots. Upgrading and retrofitting with new welding power sources vs. replacing welding robots often saves time and costs. Employees do not need to be trained on how to operate new robots. Investment into new robots can be phased in over time. Spare parts that are stocked for the robots can still be used.

Topics: Robotic Welding

Robotic Welding that Takes the Weight Out of Electric Vehicle Manufacturing

As the production of electric vehicles (EV) is predicted to climb in the coming years, so is the growth of industrial welding robots used by EV manufacturers and their component suppliers. In fact, the makers of factory automation equipment have already seen a surge in investment from EV manufacturers, and they don’t predict a slowdown anytime soon.

Topics: Robotic Welding

.png)