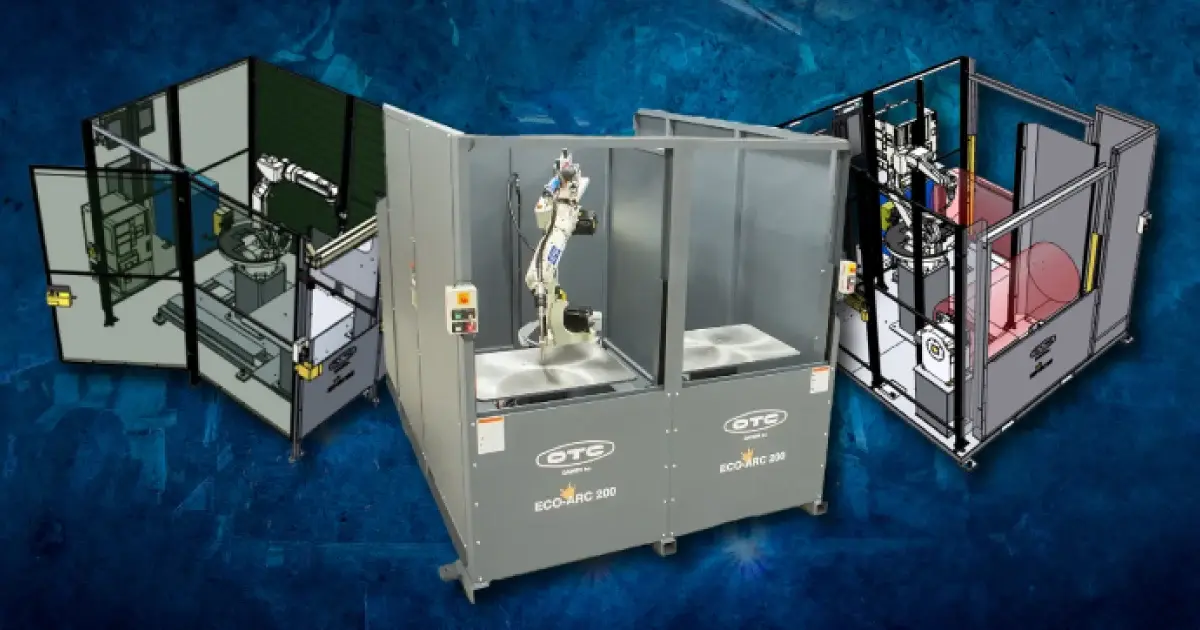

A robotic welding solution with short delivery time, quick setup and minimal downtime – sound too good to be true? Ready-to-ship welding cells make it possible to boost production immediately. Here are three ways prefab solutions help you make quick, impactful changes to your manufacturing operations.

Topics: Robotic Welding

Revolutionizing Welding: Versatile Power Sources Shaping the Future

Welding has witnessed a remarkable evolution over the years. From the early days of manual processes to sophisticated robotic welding today, welding has continuously adapted to meet the needs of various industries.

Topics: Robotic Welding, Manual Welding

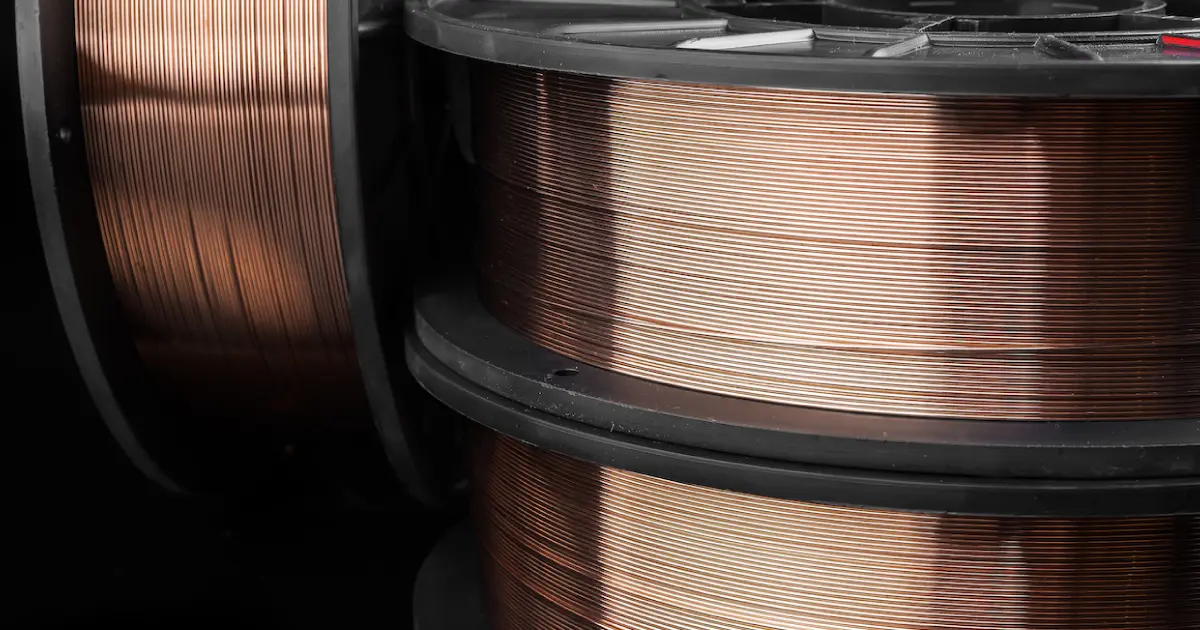

As welding technology advances, it's becoming increasingly clear that flux-cored wire might not always be the best option. In this article, we'll explore three compelling reasons why it might be time to bid farewell to flux-cored wire and embrace solid wire for your welding processes.

Topics: Robotic Welding, Manual Welding

The welding world has long been acquainted with anti-spatter sprays and gels, which many consider necessary evils in achieving clean welds. OTC DAIHEN USA is challenging this status quo with a revolutionary approach that aims to make anti-spatter agents a thing of the past.

Topics: Robotic Welding, Manual Welding

Grinding and abrasives have long been necessary but costly in welding to achieve precision and quality finishes. Manufacturers are now finding considerable savings in time and costs with OTC DAIHEN’s innovative welding technology that cuts down the need for grinding and abrasives.

Topics: Robotic Welding, Manual Welding

For decades, helium has been a critical component in welding processes, prized for its inert properties and performance in high-temperature applications. However, its escalating costs and fluctuating supply have long posed challenges for manufacturers.

Topics: Robotic Welding, Manual Welding

.webp)