When you're running a production facility, it can be hard to know when it’s the right time to invest in robotic welding automation for your assembly line.

Robby the Robot. HAL from 2001: A Space Odyssey. Ash in Alien. As long as robots have been around, people have been mistrustful or downright afraid of them.

The welding industry is no exception. Many companies - and welders themselves - fear the changes a robot would bring and the jobs it could replace.

Topics: Robotic Welding

Imagine this: Your company has been producing server racks for years. You’ve gotten pretty darn good at it, good enough that a multi-billion-dollar company - let’s call them Zonama - takes notice.

Topics: Robotic Welding

Section 179 (2018): Investing in Welding Equipment and Robotics

The cap on Section 179 has gone up again for 2018, and your business may now deduct the full price of qualifying equipment, up to $1,000,000, when that equipment or software is financed from the company's gross income during a tax year. The raise (from $500,000 in 2016) is good news for businesses that were anxiously waiting to see if Congress was going to raise the deduction limit. This deduction can be used as long as the equipment is purchased and put to use between January 1 and December 31 of 2018. Now that you are able to write off the full price, you can get much more for your money and help make the most of your investment dollars.

Topics: Robotic Welding

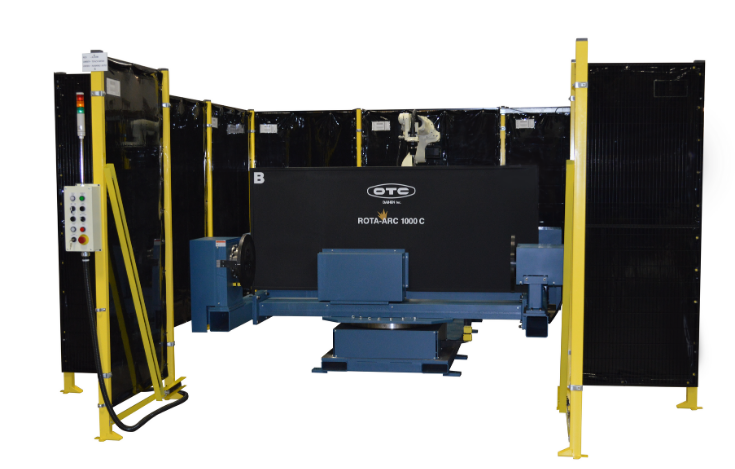

Take Welding Robotics to the Next Level with OTC Daihen Training

At OTC Daihen, we believe in offering our clients a one-stop shop for all their robotic welding needs. One option that many of our clients are still unaware of is our hands-on robotic training classes in our Tipp City, Ohio location. Can't get to Ohio? Though our clients typically get the best benefit from our well-equipped classroom, we can also bring our certified OTC Daihen technicians to you. Our training program is designed around real world manufacturing processes and can help you be more self-reliant for programming and maintenance issues. Here's a little more about the courses.

Topics: Robotic Welding, OTC DAIHEN News

Why should you consider a 7-axis robot for your welding application?

Are you having problems with weld access, torch position, interference or floor space issues? If you are, our 7-axis robot can provide you with superior weld quality and ease of use that outstrips the competition. But what advantages does it provide over the more common 6-axis welding robot? Here are some of the best benefits our customers have noticed.

Topics: Robotic Welding

.png)

.png)