Topics: Robotic Welding

Topics: Robotic Welding

Keeping your robotic welding systems in top shape is key to maintaining consistent productivity and minimizing downtime. With a solid maintenance plan, you can catch minor issues before they become costly problems.

Topics: Robotic Welding

Don’t Get Left Behind: How Small Shops Can Automate Welding Now

Welding automation is no longer just for large-scale operations. Today, small manufacturers and job shops have more options than ever — from compact collaborative welding robots (cobots) to high-performance industrial welding robots. With an ongoing shortage of skilled welders, automating welding processes is not just an advantage — it’s becoming a necessity.

Topics: Robotic Welding

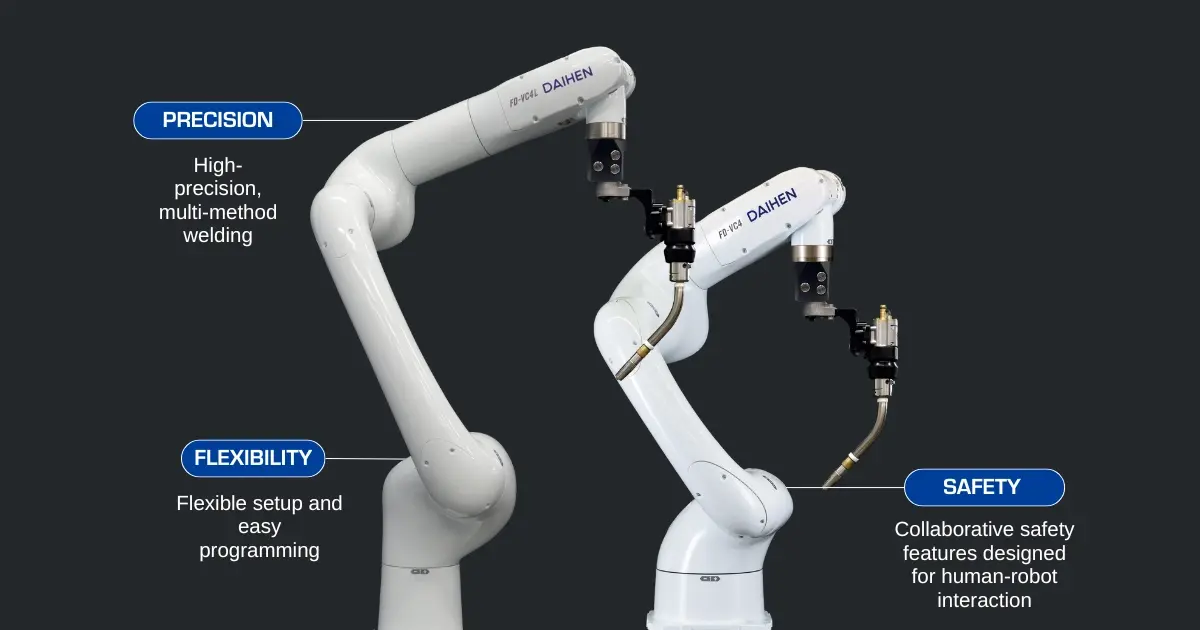

Collaborative robots (cobots) have revolutionized manufacturing, offering automation that is accessible, efficient, and safe — or so the myths claim. At OTC DAIHEN, we’ve heard these promises before, and we know the reality isn’t always so simple. That’s why we’ve developed our cobots with solutions to common challenges, proving that you don’t have to compromise on quality or performance.

Topics: Robotic Welding

Tired of complex automation slowing down your manufacturing process? OTC DAIHEN’s FD-VC4 and FD-VC4L cobots are designed with this in mind, offering advanced capabilities without the complexity often associated with industrial automation. Here’s how we make sure that using our cobots feels intuitive, efficient and user-friendly for operators of all experience levels.

Topics: Robotic Welding

.webp)