As the production of electric vehicles (EV) is predicted to climb in the coming years, so is the growth of industrial welding robots used by EV manufacturers and their component suppliers. In fact, the makers of factory automation equipment have already seen a surge in investment from EV manufacturers, and they don’t predict a slowdown anytime soon.

Here’s what EV manufacturers seek in robotic welding:

High-Quality Welds on Thin Coated Sheet Metal

One of the big selling points of electric vehicles is the miles they can travel before recharging the battery. For an EV manufacturer, the key is finding a way to make the vehicle as light as possible or “take the weight out.” A heavier vehicle can’t travel as far.

Therefore, EV manufacturers are using lightweight materials, such as galvanized coated steel and aluminum. The challenge is creating strong, consistent welds without burn-through on these materials.

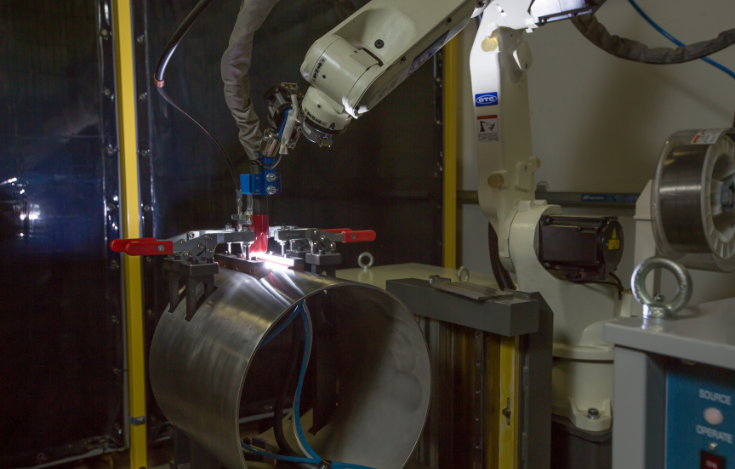

At OTC DAIHEN, leading electric vehicle manufacturers have turned to us for our 7-axis welding robots and Welbee II power sources, which include advanced software programming and a patented WavePulse technology that outperforms competitor welding solutions.

Our D-Solution welding mode allows for a lower porosity weld with higher travel speeds, more stable arc, good penetration and a good bead profile on galvanized and galvannealed-coated steels. It is programmed into the OTC DAIHEN welding robot for the highest production efficiency.

Strong Welds on Aluminum Battery Compartments

Another critical area in the production of electric vehicles is the battery compartment, which is made of aluminum. It must have high-strength welds on the body to hold the heavy battery. This requires a strong weld that is consistent every time.

Therefore, EV manufacturers are integrating more welding robots into the process to gain that high-quality, consistent weld shift to shift. Also, those welding robots must be proven on aluminum.

For aluminum welding, our WavePulse technology virtually eliminates even the finest spatter and achieves a TIG-like bead appearance. This low-frequency pulse GMAW process modulates both wire feeding and pulse current, achieving beautiful high-speed welds with improved metallurgical benefits.

For aluminum welding, our WavePulse technology virtually eliminates even the finest spatter and achieves a TIG-like bead appearance. This low-frequency pulse GMAW process modulates both wire feeding and pulse current, achieving beautiful high-speed welds with improved metallurgical benefits.

For reducing and eliminating burn-through on thin aluminum, our AC-MIG and Synchro-feed robotic welding modes control the heat input with the added side benefit of reducing distortion due to heat.

These advanced welding technologies have established OTC DAIHEN as the market leader in welding aluminum.

Welding Robots to Mass Produce Electric Vehicles

Manufacturers are also seeking ways to mass produce electric vehicles to cut costs and make them an affordable option for more people.

Again — enter welding robots. Automation allows for mass production, which in turn produces economies of scale.

The integration of robots also helps overcome the skilled labor shortage many manufacturers face today and predict into the future. In 2021, U.S. factories ordered more robots than ever before (a 37% increase from the previous year) in the first nine months as they struggled to recruit labor, according to the World Economic Forum.

Manufacturers are automating everywhere, and that trend will only continue to grow.

OTC DAIHEN — Your Robotic Welding Solution

At OTC DAIHEN, our welding robots and components are highly versatile and come in a wide range of options and capabilities. All have seamless digital connections with OTC DAIHEN welding power sources.

Whether you need a compact design, maximum mobility, extended reach or other features, an OTC DAIHEN welding robot can do it faster, easier and better than others on the market.