As productivity demands continue to rise, it’s time to get rid of the old mindset that you can’t MIG weld aluminum with 1/16” wire. Yes, you can! And, it can be done in a way that is smooth for welders and increases weld quality and productivity.

How? The answer is in the welding power source you are using.

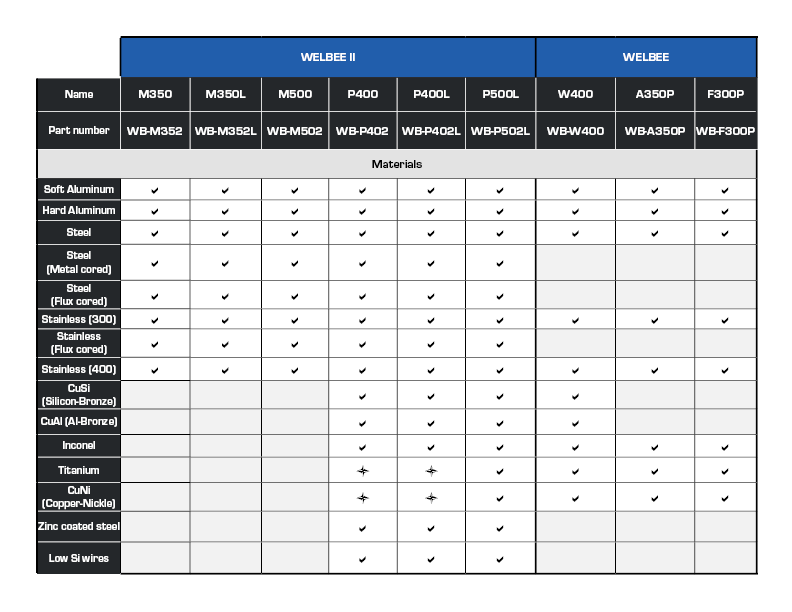

OTC DAIHEN’s Welbee II welding power sources have the advanced welding technology that aluminum manufacturers need to reach the higher productivity numbers they are faced with today.

Gain Quality and Efficiency with Larger Diameter Weld Wire for Aluminum

A smaller diameter welding wire is often the go-to when selecting wire for welding because it’s easier to control the weld puddle. However, the output is slower and strength weaker than a larger diameter wire.

Larger diameter welding wire is often thought of as being cumbersome and more challenging to find the “sweet spot” for the highest quality weld. However, the larger diameter wire brings faster feedability for higher productivity and a stronger weld.

Aluminum manufacturers now can have the best of both worlds with a Welbee II welding power source that has the advanced technology to weld aluminum with 1/16” diameter wire just as if you were welding with 3/64” diameter wire.

The OTC DAIHEN Welbee II technology allows the pulse wave to form smaller droplets, creating the same stability a welder typically finds in the smaller diameter wire. Welbee customers have said production welders have transitioned to the thicker wire seamlessly, not even noticing a difference.

The Welbee welding power source’s pulse wave virtually eliminates even the fine spatter from aluminum MIG welding. In addition, you can easily achieve a TIG-like bead appearance with OTC DAIHEN’s patented Wave Pulse process. This low-frequency pulse GMAW process modulates both wire feeding and pulse current, achieving beautiful high-speed welds with improved metallurgical benefit.

When to Switch to Larger Diameter Wire for Welding Aluminum

The benefits of switching to an OTC DAIHEN Welbee II model are obvious. But when is the right time to make the switch to a larger diameter wire in welding?

There are two key signs:

- You need to get parts out the door faster. Whether you are faced with supply chain issues, labor shortages, increased market demands or all of the above, you are still tasked with getting production out the door. An advanced welding power source that allows you to weld with larger diameter wire provides faster welding capabilities and higher quality, meaning less rework.

- You are faced with a new product or application. If you have a new product on the line that requires faster wire feed speeds or thicker welds, now is the time to spec out a solution that brings together the highest quality and productivity.

While upgrading power sources may require a capital investment, the increase in throughput often provides quick payback. If you are considering a new welding power source or welding system, we recommend you first have an OTC DAIHEN welding cost analysis in hand.

Our welding expert can calculate for you the potential financial gains over a targeted payback period. Learn how to request your free welding cost analysis here.