Welding Power Source Buyer’s Guide & Comparison Chart

The Welbee welding power source has long been known as a leader in innovation, efficiency and high quality in arc welding. And now, they’ve done it again with the introduction of the new Welbee II series.

OTC DAIHEN R&D Engineer Larry Barley, CWI, CRAW-T, has put together this Welbee II Buyer’s Guide to help you select the best arc welding unit for your shop floor or for your distribution customers.

The new features of the Welbee II include an updated control panel, additional operating functions and an on-screen display of the supported functions, errors and data tracking.

Want to see a weld demonstration? You got it!

Contact us or request a weld demo today. Click to View the Comparison Chart

Click to View the Comparison Chart

Welbee II New Functions and Benefits

Larger, Upgraded Display Panel

The new display panel on the Welbee II incorporates changes that were requested by our customers.

Instead of matching up LEDs with text on the panel to determine what the weld settings are, the new display has a 7-line readout of the main settings. This, along with two 40% larger digital displays for Amps/WFS and Volts/(+/-), gives the operator an easier overview of the machine settings when welding.

In the ready-to-weld mode, the upgraded display shows the welding mode, material, gas type, wire diameter, travel speed and any special conditions. Pushing the menu button pulls up the next screen, which allows you to access additional features, such as functions, load job, save job, weld monitor, key lock and backup (data).

Additional Operating Functions

Additional operating functions now allow the welder to select a variety of settings to enhance the welding operation. The operating functions also are displayed on the new display panel with a description of the function and ranges that are applicable to help the welder in selecting the best function for his job.

One of the new operating functions is the Intermittent Welding Mode. In this function, the welder can be set for an "ON" welding time and an "OFF" welding time. This allows the unit to be set up for intermittent welds being made on a tractor or side beam device. It can also be used in areas that have a bad joint fit-up.

Another function that brings efficiency is Function F38 that allows the welder to easily switch the power leads and weld in the DCEN mode. The high quality of OTC DAIHEN and Welbee power sources has been due in large part to our real-time monitoring of the power supplied to the arc and our ability to change that power prior to spatter creation. This new function makes it easier than ever before to monitor the polarity and voltage signals.

A Welding Guide with Data Tracking

Another new function is the on-screen welding guide. You select the weld joint, base material, weld size and the machine provides the suggested parameters for this application. The updated weld data recorder will automatically display up-to-date data on the welds upon completion of each weld. The updated data includes weld times, and machine "ON" times.

NEW-PULSE for Mild Steels

The Welbee II has updated welding software for high-speed welding of mild steel. This New Pulse technology decreases voltage, keeps spatter to a minimum while reducing undercut at the weld toes.

Special Mode for Low Silicon Solid Wires

Another advancement is a special mode for newer, low silicon solid wires. Low silicon wires have been developed for automotive underbody components to reduce the amount of slag spalling on powder-coated parts. However, the chemistry of these wires makes the arc characteristics with conventional programming poor at best. The updated Welbee software provides a stable arc with a good bead appearance and minimal spatter, even on zinc-coated materials.

New Software for More Stable Arc on Aluminum

Manufacturers who weld aluminum parts and products know welding heavy plate can be a challenge. The updated Welbee II includes software for 5000 series wire on heavy plate to provide a more stable arc, more constant current, good penetration and good bead profile on aluminum.

The Welbee II Product Line

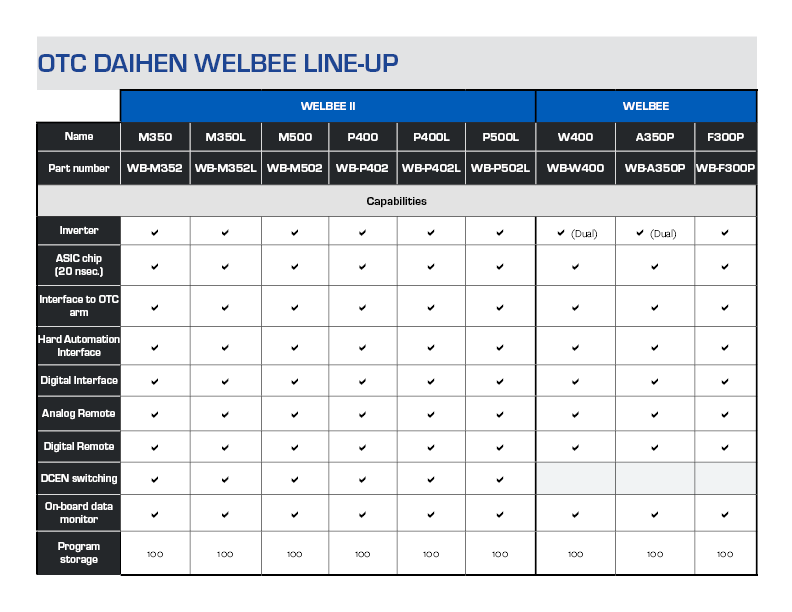

All of the Welbee welding power sources have a very similar architecture, which includes:

- They are all inverter-based.

- Each has the capacity to store 100 programs of your choice.

- All are driven by a set of specially made microchips (ASIC) that have a 20 nanosecond (1 / 50,000,000 sec.) processing speed.

- They have built-in interface boards that allow each of them to be used manually, semi-automatically, in hard automation or robotically.

- Self-diagnostics and basic data collection are built in.

- There is a USB port to allow the download of data and programs in addition to uploading new software.

- The mechanical design of each unit shares most of the same structure. Also, the top and right-hand side that contain the microelectronics are virtually sealed from the outside. This greatly reduces the influence of damaging environmental elements such as grinding dust, dirt and high moisture from affecting the more delicate components.

- The left and central areas of the units are a wind tunnel design. With air pulled in from the left side center, it is projected across the heat sink elements by on-demand fans. This design requires that the cooling air only has to travel over 1/2 the depth of the unit and then only draws in potentially dirty shop air when cooling is needed.

- Being inverter-based units also allows them to be both Constant Voltage (CV) and Constant Current (CC) units. CV is conventionally used for the GMAW and FCAW processes, and CC is used for SMAW, GTAW and Plasma Arc Welding (PAW). Some units also have DC Pulse and DC Wave Pulse capabilities

Welbee II M350 Welding Power Source

(WB-M352)

Starting at the low end of our spectrum, which is higher than a lot of the competition, we have the Welbee M352.

This 350A unit is a DC -CV / CC unit that can GMAW weld steel, stainless steel, aluminum, FCAW, DC scratch start GTAW and SMAW. The unit, along with all the other Welbees, has excellent short-circuiting transfer with minimal spatter by utilizing our Controlled Bridge Transfer (CBT) waveform technology.

The CBT uses our very fast circuitry to see a short as it is happening, then alter the power in such a way that the short is cleared more like pulling taffy apart than the explosion of a fuse blowing up.

The M352 is great for thinner parts, parts that have fit-up issues and welding operations that do not require pulsed welding. In addition, this is a single or 3-phase unit running on 200/230 or 460 VAC.

Welbee II M500 Welding Power Source

(WB-M502)

The big brother to the M352 is the M502.

The M502 has the same DC -CV / CC output characteristics that can GMAW weld steel, stainless steel, aluminum, FCAW and DC scratch start GTAW and SMAW but can go up to 500 amps. It also has optional software to do carbon arc gouging.

The M502 is great for thinner parts all the way up to heavy plate weldments and welding operations that do not require pulsed welding. The Welbee M502 will only operate on 3-phase 460 VAC.

Welbee II M350L Welding Power Source

(WB-M352L)

One step up is the M352, we have the Welbee M352L. In addition to all the features noted above for the M352, the M352L adds Low Spatter mode to the mix. Low Spatter mode takes the DAIHEN CBT to the next level as it creates a very soft short-circuiting arc in the steel and stainless steel (300 & 400) modes. Low Spatter mode is very useful on very thin sheet metals and for root passes in pipe welding. In addition, this is a single or 3-phase unit running on 200/230 or 460 VAC.

Welbee II P400 Welding Power Source (WB-P402)

The biggest seller in the Welbee line is the P402. This 400A unit brings with it all the features and benefits of the M352 and adds Pulse and Wave Pulse modes and some additional metals/filler options to the welder. In addition, this is a single or 3-phase unit running on 200/230 or 460 VAC.

Welbee II P400L WeldingPower Source (WB-P402L)

The newest model in the Welbee line is the P402L. This 400A unit brings with it all the features and benefits of the P402 with CV, Pulse and Wave Pulse modes and adds the Low Spatter Mode found in the M352L and P502L. In addition, this is a single-phase 200/230 Vac or 3-phase 200/230/460 VAC.

Welbee II P500L Welding Power Source (WB-P502L)

The big boy in the Welbee line is the P502L. This 500A unit brings with it all the features and benefits of the M352L, P402 and P402L with some extra power. It is equally adept at welding 1mm aluminum as it is a 1" thick steel plate thanks to its inverter base and high-speed computer programming. The P502L unit will run only on 3 phase 460 VAC.

Welbee W400 Welding Power Source (WB-W400)

The most capable Welbee in the line is the W400. This 400A unit brings AC GMAW welding. AC Pulse and AC Wave Pulse add another dimension to GMA welding.

If arc blow is a consistent problem, AC Pulse or AC Wave Pulse often eliminate this concern. If you need to weld very thin materials at a decent (GMAW) speed, the AC Pulse may be your ticket. The welding speed and lower amperage on thin materials also have the effect of reducing distortion and warping.

At the other end of the power spectrum, in the AC Pulse mode, it has the ability to control dilution when doing overlay work. In AC Pulse mode, there is more wire deposited at a given amperage than in the DC mode and with that, a thicker build-up and less dilution are attained. In some cases, this allows a single pass overlay to meet the customer’s requirements, where two passes were required with a DC power source.

All of these features are due to the dual-inverter in this machine, which allows it to make the polarity switch from negative to positive without extinguishing the arc. This W400 unit will only operate on 3-phase 460 VAC.

Welbee A350P Welding Power Source (WB-A350P)

The Welbee line would not be complete without a superb GTAW (TIG) machine. The A350P unit is the third generation of GTAW power sources that has a somewhat unique AC + DC hybrid mode. In this mode, the unit switches from AC (for cleaning) to DC (for penetration and speed) and back via adjustable programming.

Most suitable for heavier aluminum work, you can adjust and set the parameters to meet your welding needs. Of course, there are the standard TIG settings like DC, DC Pulse, AC (standard, soft and hard), AC Pulse, EN balance, AC frequency and others. All of these features are due to the dual inverter in this machine, which allows it to make the polarity switch from negative to positive without extinguishing the arc. A Welbee A350P will only operate on 3-phase 460 VAC.

Welbee F300P Welding Power Source (WB-F300P)

The Welbee F300P is a premier Plasma Welding system. This unit can be coupled to 6 different plasma torches that have been designed to complement the range of materials that are being welded. The six torches based on the amperage required are 15A, 70A, 100A, 150 A, 200 A, and 300A.

Each of these uses a unique DAIHEN 3 gas shielding system that enhances the plasma welding quality. The F300P is driven by the same microprocessor-controlled inverter as are the other Welbee units. The unit can be set up for manual, hard automation or robotic welding. The F300P runs on 3 phase 460 VAC and requires a separate water chiller to cool the torch.

OTC DAIHEN - YOUR ONE-STOP SOLUTION

At OTC DAIHEN, we are your one-stop, advanced welding and robotic system supplier. We produce everything you need - welder, robot, torch, wire feeder and all the know-how to put it together and apply it to your toughest welding challenges.

Ready for a Welbee II demonstration?

.png?width=250&name=larry-inline%20(1).png)