As welding technology advances, it's becoming increasingly clear that flux-cored wire might not always be the best option. In this article, we'll explore three compelling reasons why it might be time to bid farewell to flux-cored wire and embrace solid wire for your welding processes.

The welding world has long been acquainted with anti-spatter sprays and gels, which many consider necessary evils in achieving clean welds. OTC DAIHEN USA is challenging this status quo with a revolutionary approach that aims to make anti-spatter agents a thing of the past.

Topics: Robotic Welding, Manual Welding

Grinding and abrasives have long been necessary but costly in welding to achieve precision and quality finishes. Manufacturers are now finding considerable savings in time and costs with OTC DAIHEN’s innovative welding technology that cuts down the need for grinding and abrasives.

Topics: Robotic Welding, Manual Welding

For decades, helium has been a critical component in welding processes, prized for its inert properties and performance in high-temperature applications. However, its escalating costs and fluctuating supply have long posed challenges for manufacturers.

Topics: Robotic Welding, Manual Welding

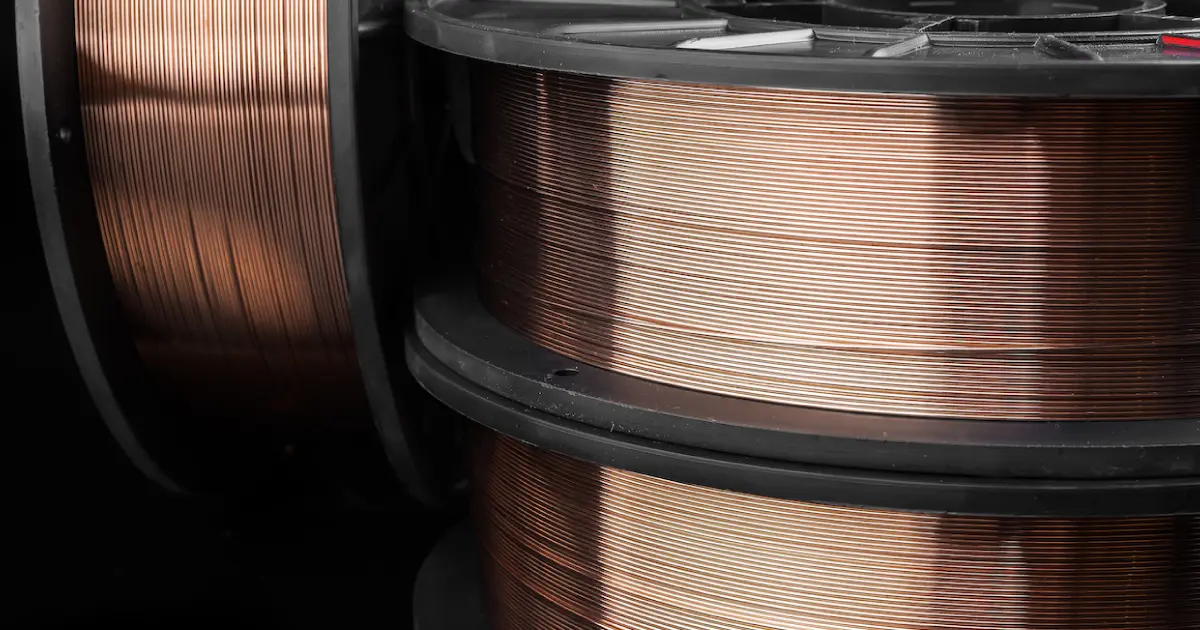

Is the welding wire you're using too small, too large or just right? Welding wire is an essential component of the welding process as it serves as the electrode and filler material, melting and fusing with the base metal to create the joint.

The welding wire diameter can significantly influence the quality of the weld, its strength and the overall efficiency of a welding production line. Choosing the right welding wire is key to production efficiency and cost savings.

Topics: Robotic Welding, Manual Welding

Topics: Robotic Welding, Manual Welding

.webp)

.png)