Working in a welding facility can be one of the hardest jobs on the planet. There's high voltage electricity, serious heat and vaporized metal particulates. How do you keep your workers safe? Here are a few tips to help create a healthy work environment in your production facility.

Topics: Manual Welding

How to cut welding manufacturing costs with better weld quality

When you're in manufacturing, every extra expense adds to your overhead and cuts into your productivity. How do you lower your labor, material and equipment costs? At OTC Daihen, we know welding. Here's our look at how to reduce welding costs on your production line.

Topics: Manual Welding

What part of the welding process most affects the bottom line?

When you're in business creating products, welding process profitability may seem like a vague concept. But welding operation costs can cause direct impacts on your profitability. Which area of welding causes the highest change in your bottom line? Learn which one has the strongest impact here.

Topics: Manual Welding

The blog was originally posted in 2016 and updated in 2023 with new information.

When you're under a deadline to complete production, the last thing you need are quality issues. Unfortunately, weld porosity is a common problem in welding applications. Fortunately, it's also relatively easy to fix. How do you reduce porosity in your production line? We've taken a look at the causes of weld porosity and found the easiest ways to reduce it.

Topics: Manual Welding

When your operation is dealing with aluminum welding, it can seem as though there's a whole new world of issues to troubleshoot. Porosity, oxidation, weld cracking, wire burn-backs and many more issues tend to plague production lines around the world. One common concern is whether a push-pull gun or a push gun works best when welding aluminum. In this piece, we'll take a solid look at what the advantages and disadvantages are of each type of gun and how to best incorporate them into your production line.

Topics: Manual Welding

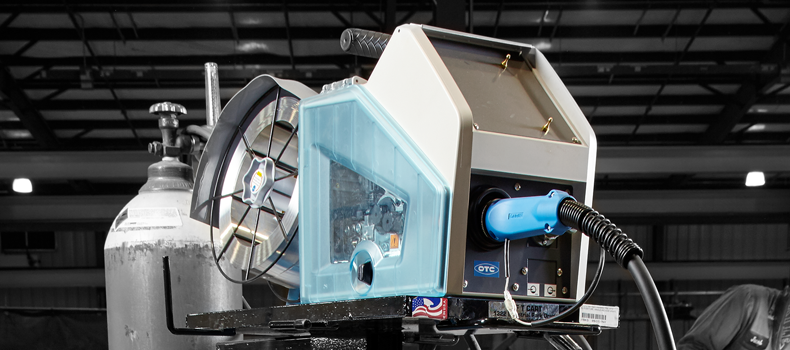

When you're involved in assembly line management, there are a wide range of inputs and processes that can affect your overhead and, by extension, your profitability. When your assembly line slows down, it costs labor and production. Processes that keep your line running efficiently directly impact your profitability. One area where many companies find room for improvement is in their welding processes. Fine tuning the process to reduce slag and spatter, improve welding times and provide better quality control results can come from a range of changes. One area where improvement can be found is in choosing to use a dual wire feeder or a single wire feeder. Here's a quick overview of each welding wire feed and the advantages and disadvantages of each.

Topics: Manual Welding

.webp)