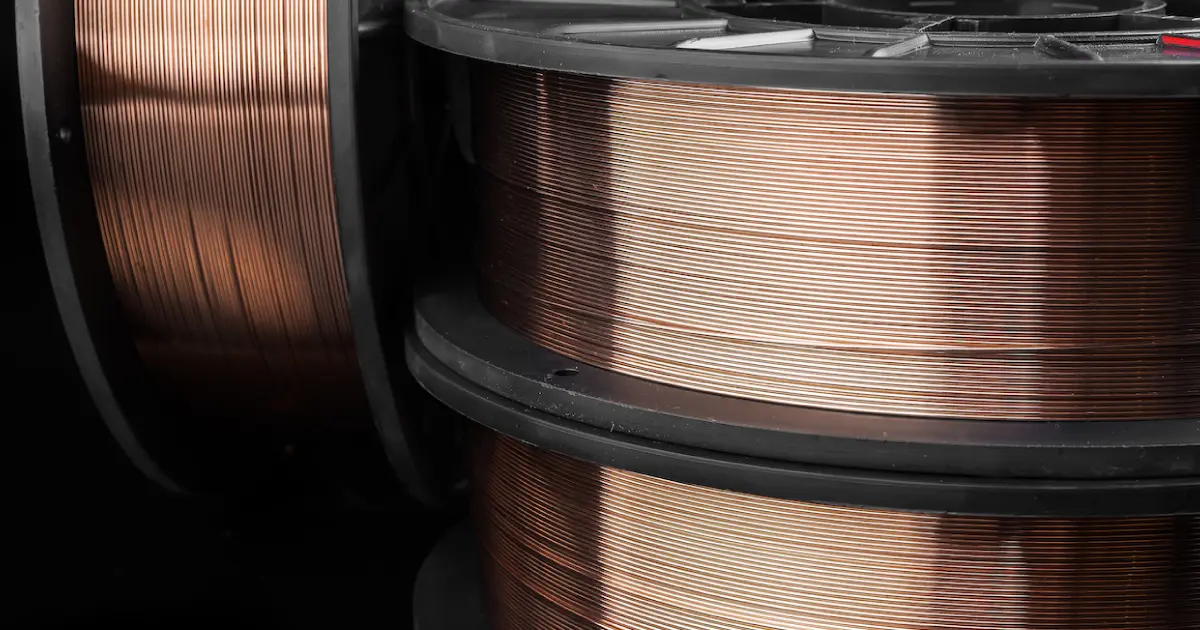

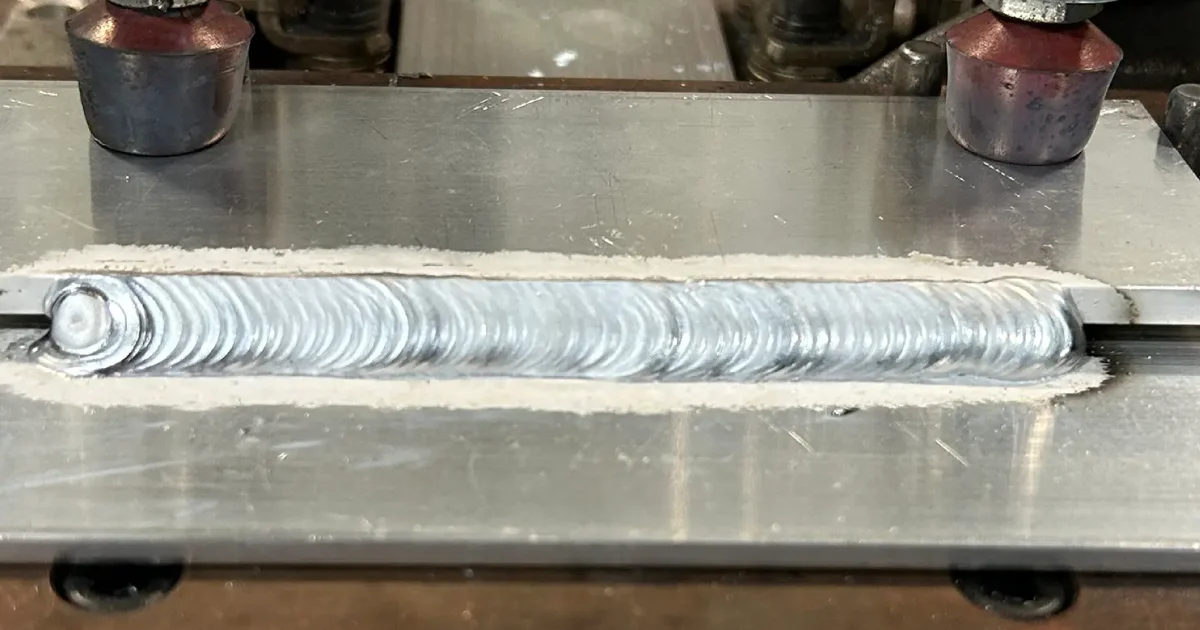

As welding technology advances, it's becoming increasingly clear that flux-cored wire might not always be the best option. In this article, we'll explore three compelling reasons why it might be time to bid farewell to flux-cored wire and embrace solid wire for your welding processes.

Subscribe!

Get Keeping It Clean, a monthly enewsletter with all the latest in welding and robotic automation.

OTC DAIHEN Blog

Latest insights on arc welding, robotic welding, new welding technologies and more.

Featured Article

As welding technology advances, it's becoming increasingly clear that flux-cored wire might not always be the best option. In this article, we'll explore three compelling reasons why it might be time to bid farewell to flux-cored wire and embrace solid wire for your welding processes.

Topics: Robotic Welding, Manual Welding

Browse by Categories

Recent Articles

Published on May 2, 2024

Topics:

Robotic Welding,

Manual Welding

Published on April 7, 2024

Topics:

Robotic Welding,

Manual Welding

Published on March 15, 2024

Topics:

Robotic Welding,

Manual Welding

Published on December 18, 2023

Published on November 3, 2023

Topics:

Robotic Welding,

Manual Welding

1400 Blauser Dr

Tipp City, OH 45371

Phone: (937) 667-0800

Fax: (937) 667-0885

Copyright © 2024 OTC DAIHEN. | Privacy Policy | Web Design by Marketing Essentials