As the demands of manufacturing evolve, zinc-plated steel continues to grow in popularity due to its enhanced corrosion resistance, cost-effectiveness, sustainability and versatility. However, zinc plate steel can create challenges in welding, such as weaker welds, increased spatter, porosity and a higher skill level needed.

In this blog article, we uncover the top benefits of using zinc-plated steel in production and how the revolutionary Synchro Feed Evolution technology with Push Arc mode is helping manufacturers overcome the challenges of welding zinc-plated steel.

Why Choose Zinc-Plated Steel

Enhanced Corrosion Resistance

One of the primary reasons manufacturers choose zinc-plated steel is its superior corrosion resistance. Zinc acts as a sacrificial anode, meaning that it corrodes preferentially, protecting the underlying steel from rusting. This galvanic protection creates a barrier that prevents moisture and other corrosive elements from reaching the steel surface. As a result, zinc-plated steel is particularly suitable for applications in harsh environments or industries that require long-lasting and reliable performance, such as automotive, construction, and heavy machinery.

Cost-Effectiveness

Another major factor driving the widespread use of zinc-plated steel is its cost-effectiveness. Zinc plating is relatively inexpensive compared to other protective coatings like stainless steel or aluminum.

Sustainability

Additionally, zinc is an abundant and easily recyclable material, which contributes to the sustainability of the production process. This eco-friendliness appeals to companies looking for ways to reduce their carbon footprint.

Versatility

Zinc-plated steel's versatility is yet another reason it's a popular choice among manufacturers. The plating process can be easily adjusted to achieve varying levels of thickness and corrosion resistance, depending on the intended application.

Aesthetic Appeal

Furthermore, zinc-plated steel can be treated with chromate conversion coatings, which come in many colors and finishes. This makes it possible to achieve both functional and aesthetic requirements for various industries.

Drawbacks When Welding Zinc-Plated Steel

Although zinc-plated steel offers many advantages, there can be potential drawbacks when welding it. While it is undoubtedly possible to weld steel that has been zinc plated, several problems can stand in the way of successful welding, including:

Weld Quality

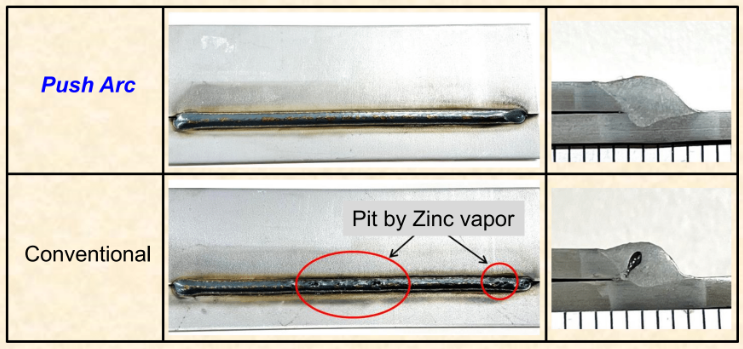

When zinc plating is exposed to the high temperatures involved in welding, zinc vapors rapidly escape from the metals, causing porosity, pitting and blowholes. These issues lead to weaker welds, higher costs associated with rework and a final product that is less attractive.

Weld Spatter

Zinc-plated steel can produce a large amount of weld spatter, which are molten droplets of metal that blemish the weld. Spatter requires more grinding and cleanup, which leads to less production and higher costs.

Welder Training and Availability

Welding zinc-plated steel requires specialized training and techniques to ensure strong, high-quality welds. The needed technical experience can lead to higher costs for companies in one of two ways. The first is wasted time and effort trying to recruit qualified welders at a time when, according to the American Welding Society, the welding industry will face a growing shortage of about 375,000 welders in 2023. The second is the opportunity cost and the cost of lowered production required to train less experienced welders to be proficient in welding zinc-plated steel.

New Technology Resolves Challenges Welding Zinc-Plated Steel

As a global leader in robotic and manual welding solutions, OTC DAIHEN has been at the forefront of innovations to overcome challenges such as welding zinc-plated steel. Our revolutionary Synchro Feed Evolution technology with Push Arc mode addresses many common pain points found in welding zinc plating. Unlike other technologies, Synchro-feed Evolution can:

Create a Larger Molten Pool for Higher Weld Quality

The Synchro Feed Evolution Push Arc mode enlarges the molten pool, which facilitates the release of zinc vapor and prevents pitting and the formation of blow holes for a higher-quality weld.

Enhance the Wire Feed Control for Less Spatter

By enhancing the wire feed control frequency, the Synchro Feed Evolution technology achieves an ultra-low spatter weld. The Push Arc Mode combines the ultra-low spatter capability with the desirable bead width and penetration depth of pulse welding. Push Arc Mode also enables ultra-low spatter on simultaneous welds of multiple units. It achieves this by predicting the timing of arc generation and controlling droplet transfer without the need to rely on voltage feedback.

Decrease Welder Training Time

OTC DAIHEN’s welding solutions are user-friendly, with on-screen displays of functions, errors and data tracking to help all levels of welders achieve optimal results. Its most advanced features include real-time monitoring to alert changes needed before spatter creation, easy monitoring of polarity and voltage signals and more.

Also, OTC DAIHEN’s team of experts provides extensive training to companies' existing staff on how to program and manage new welding solutions to optimize productivity and minimize downtime.

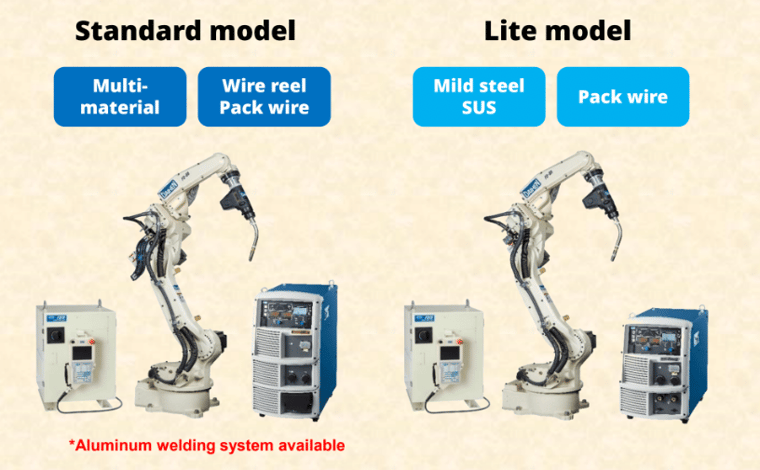

Synchro-feed Evolution Models

OTC DAIHEN is your one-stop welding system supplier. We produce everything you need — welder, robot, torch, wire feeder and all the know-how to put it together and apply it to your toughest welding challenges.

Our Synchro Feed Evolution with the Push Arc mode is available in standard and lite models. Contact your regional OTC DAIHEN rep for more information.