.gif?width=734&name=blog-large-area-fabrication-webinar%20(1).gif)

How far from the source can you weld aluminum with your current fabrication welding system? The typical answer is “about 10 feet” or “not far enough.”

In this article and accompanying on-demand webinar, we are going to bust large area fabrication welding myths and show you:

- How to push aluminum 13 feet,

- How to push-pull aluminum almost 40 feet,

- And how to push-pull aluminum 100 feet and beyond!

Large Area Fabrication Welding Myths -- Busted!

The welding community harbors some deep-seated conventions when it comes to large-area fabrication welding, questioning the reliability of push-feeding aluminum wire. Myths include:

It’s impossible to push-feed aluminum welding wire.

Push-pull torches are unreliable and expensive.

Pull torches are your only option for large-area fabrication welding.

Large area fabrication is a safety/liability nightmare, which may include tripping hazards, enclosed/cramped workspaces and heavy lifting requirements

Read on and watch the webinar to see us bust these four myths and discover the latest innovations for welding further … and further ... away from your welding power source.

How to Push Aluminum Beyond 10 Feet

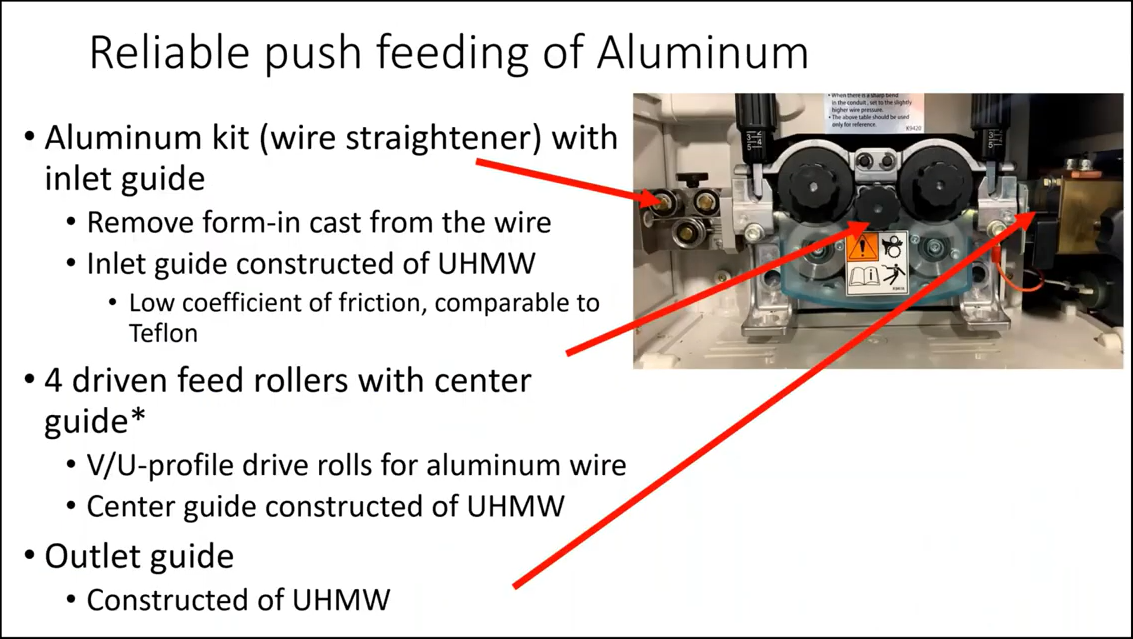

With an OTC DAIHEN Wire Feeder, you can gain a reliable solution for push-feeding aluminum beyond the typical 10 feet. Take a look at the anatomy of an OTC DAIHEN Wire Feeder:

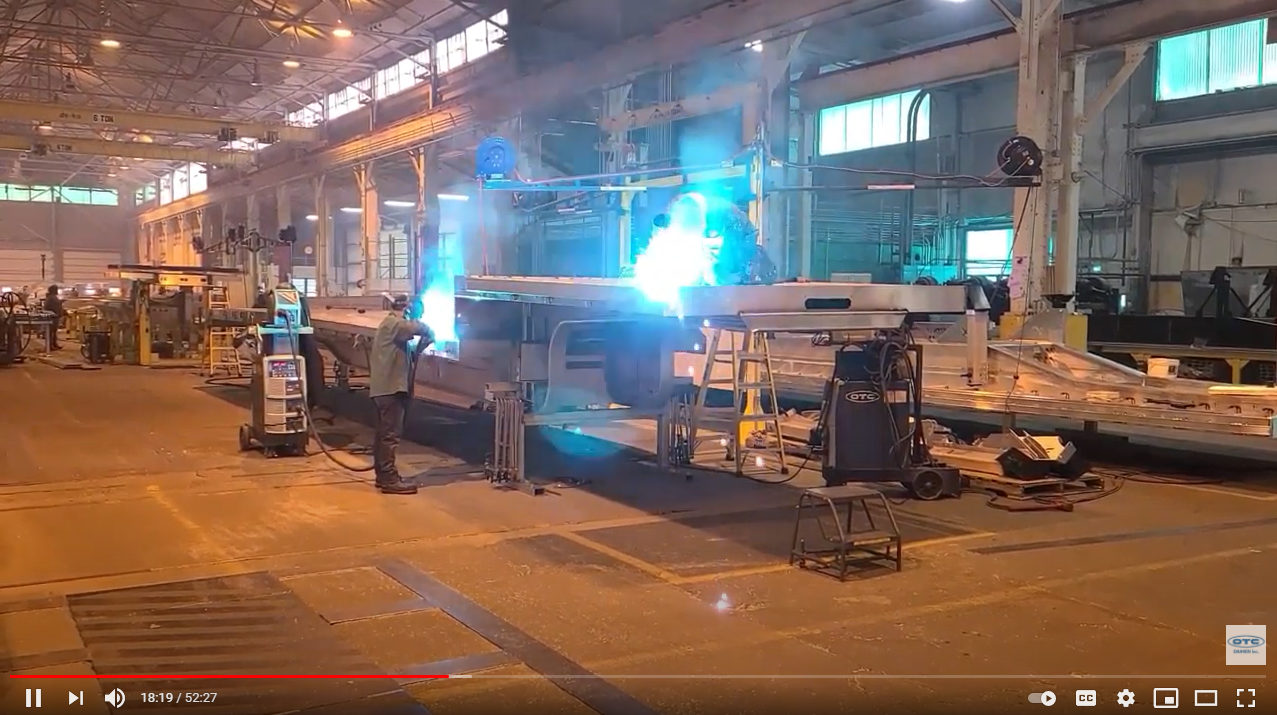

Shown below is a customer manufacturing trailers with torches pushing aluminum wire out 13 feet, using an OTC DAIHEN Wire Feeder. Learn more in this comparison of OTC DAIHEN torches.

Ready to see it in action? Go to 15:53 in the webinar to see a demo on how to set the feeding tension in an OTC DAIHEN Wire Feeder.

How to Push-Pull Aluminum Almost 40 Feet

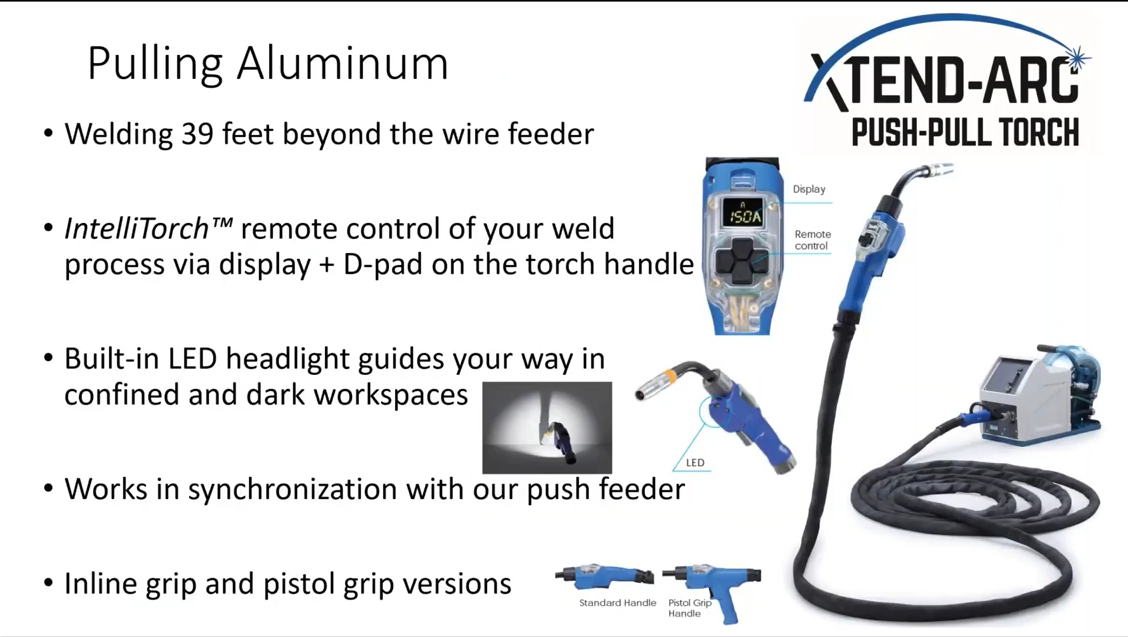

To extend even farther, our XTEND-ARC Push-Pull Torch allows you to get 39 feet beyond the wire feeder. It also incorporates our IntelliTorch™ technology to remote control your weld process. It’s easy to use, even with a welding glove on. Our XTEND-ARC Push-Pull Torch includes:

Watch a demo! Go to 20:00 in the webinar to see a demo of the XTEND-ARC Push-Pull Torch user interface.

How to Push-Pull Aluminum 100 Feet & Beyond!

One of our newest products, and the future of welding, is the XTEND-ARC Inline Assist Feeder, which greatly expands the range of welding systems. It’s durable, extremely lightweight and made to be portable. And it’s capable of welding 100+ feet beyond the welding power source. Our XTEND-ARC Inline Assist Feeder includes:

See it in action! Go to 27:14 in the webinar to see a demo of the XTEND-ARC Inline Assist Feeder and its user interface.

NEW UPDATES to the XTEND-ARC Push-Pull Torch

In 2022, OTC DAIHEN made several mechanical updates to the XTEND-ARC air-cooled push-pull welding torch to improve productivity even further. These updates include:

- Additional data logging functions: welding time, maximum torch temperature and duty cycle.

- Additional error logging functions: torch error codes, amp setting at the time of error, duty cycle at time of error and weld time since last error.

- Improved temperature monitoring functions to provide warnings when nearing the upper temperature limits.

- Torch body improvements to allow for easier service of internal components.

- Increase of the power cable size by 43% to improve the duty cycle from 35% @ 250A (150A @ 100%) to 60% @ 280A (215A @ 100%).

- Changing the torch lead sheath to a hook and loop type closure to allow for easier servicing of the cables and hoses.

- Improving control cable attachment points to prevent separation of the fine control wires during usage.

The Webinar

View the full webinar to learn more about how customers gained 15% more arc-on time, get DIY solutions on how to expand your range of motions, and see additional products to increase safety and productivity for your large area fabrication.