Ready to upgrade or replace your Welbee arc welder? Looking to expand machine capabilities for higher quality welds? New to the Welbee series? Or maybe you're a distributor looking to educate your customers on the many benefits of a Welbee arc welder?

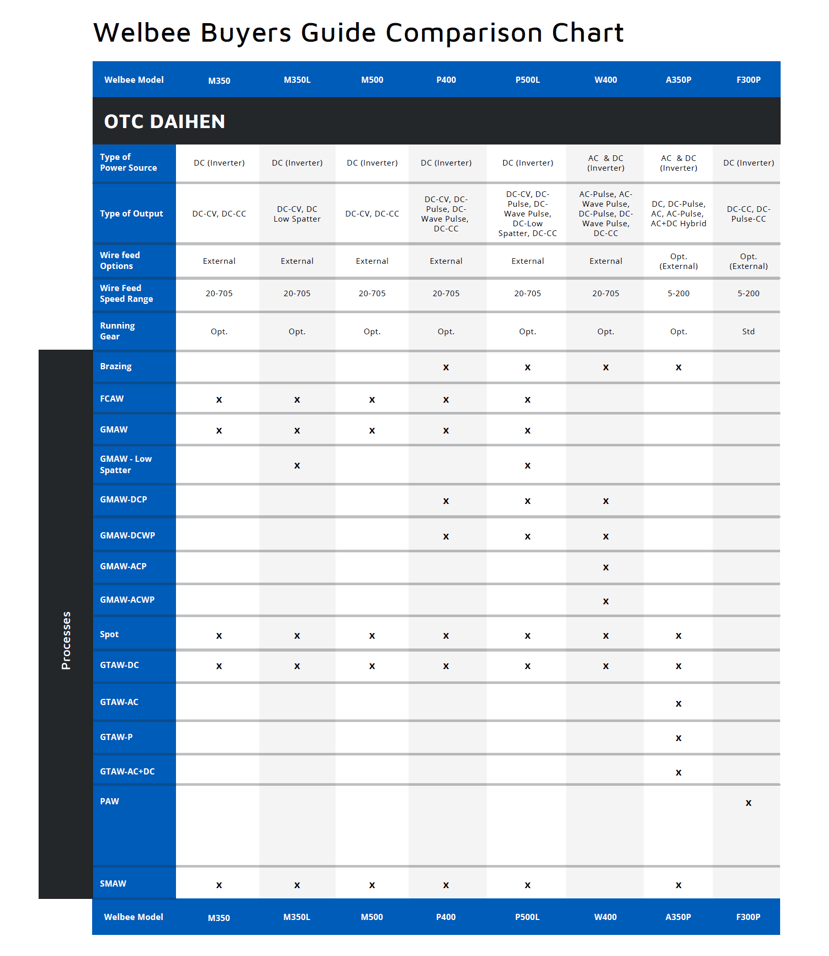

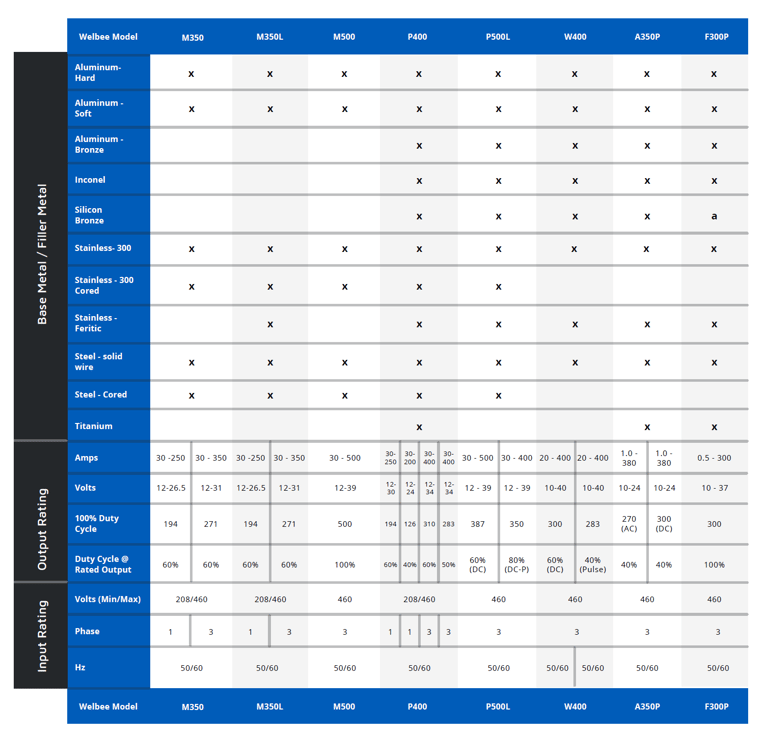

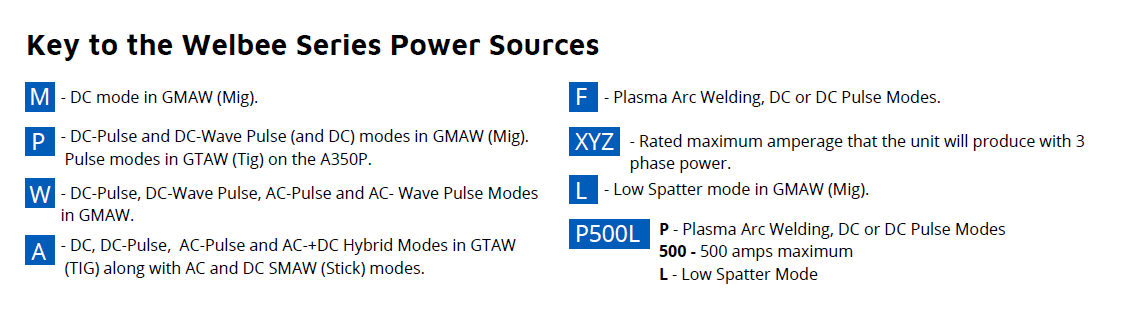

In any scenario, our OTC DAIHEN Welbee ultimate buyer’s guide has you covered. This guide will help you select the best arc welding unit to bring the highest efficiency and best value to your shop floor. Get started by answering the series of questions below and using our handy Welbee model comparison chart.

Need a little more information or want to see a weld demonstration? You got it!

Contact us or request a weld demo today.

Which Welbee Arc Welder Should I Buy?

The easy answer is to buy the biggest, most expensive unit that we make. After all, it can do everything but wash the dishes for you! However, that does not get you the best machine for the best value, and in fact, could lead to problems if you try to utilize features that are not ideal for the product being welded.

In some cases, the super deluxe model should be replaced with a lower-priced machine that better fits the job. You may even be able to buy two for the price of one super deluxe!

“This process of assessing the needs of the customer can be like playing 20 questions,” explains OTC DAIHEN R&D Engineer Larry Barley, CWI, CRAW-T. “We need to determine many factors so that we can come to the correct recommendation. This includes things such as materials being welded, thickness, available power, welding mode, filler metal type,etc.

“We need to examine the conditions of the joint being welded. Is it thin gauge material with varying gaps that will render the (pulse) spray mode a poor choice due to the likelihood of acting more as a cutting operation than a welding process? Is the customer welding pipe spools where the best choice may be a system that can run a low spatter mode for the root pass, then a pulse powered spray for the fill and cap passes?

“Our goal is to help them find the best solution at the best value for their shop needs.”

Start your assessment with the following questions.

Questions to Answer Before Buying a New Arc Welding Unit

- What material am I welding? Steel, aluminum, stainless? Or something more exotic such as Inconel, copper, brass?

- Do we just weld one material/type or switch multiple times and often?

- What thickness of material do we weld? 20 ga, 10 ga, 1/2" +?

- How much time does my welder actually spend welding per 10-minute interval?

Duty Cycle: (X min. / 10 min.) - Is there fitting, grinding, assembly involved or is the welder presented parts that just need welding?

- If the first option, after weld prep, is it full-on welding for X hours?

- What input (line) power is available to run the power source?

- Single or three-phase? Single-phase units will have reduced output from rated power.

- Voltage: 208, 230, 460, 575?

- What size are my parts? Cell-phone size or semi-truck size?

- Does my feeder need to be remoted from the power source?

- Do I need a push-pull torch?

- Are there welding procedures in place that need to be followed and cannot be changed or updated?

- What arc amperage and arc voltage is being used now?

- What filler wire type is being used? Solid wire, cored wire (metal-cored/flux-cored)?

- What finished part requirements am I trying to meet or exceed?

- What, if any, specifications am I using to make parts?

- What welding process and process variation am I using now?

- Is this the best process? Can I change it?

- What options for new/updated processes are there?

- Can I run samples or try the new process/equipment?

- What is my environment?

- Is this the best process? Can I change it?

- Is there a floor in my shop? Am I working on gravel or dirt floors?

- Is the shop kept above 32°F (0°C)? This is important for water-cooled units.

- What is the general cleanliness in the shop? Hospital clean, or "If we were to clean, we would use a shovel?”

- Do I need an optional spool cover?

- Is the process manual, semi-automatic, automatic or robotic?

Standard Features of the Welbee Series

With a similar overall architecture, all models of the Welbee series of arc welders include an inverter-based power source -- the most advanced available today. The inverter technology enables welders or welding automation to not only tailor the output of the power source to a specific application, but also monitor that output and arc reaction and make adjustments in real-time to create the highest quality weld.

Being inverter-based units, this also allows them to be both Constant Voltage (CV) and Constant Current (CC) units. CV is conventionally used for the GMAW and FCAW processes, and CC is used for SMAW, GTAW and Plasma Arc Welding (PAW).

The design of the units includes special features for cleanliness and cool-running systems.

The micro-electronics (located top and right-hand side) are virtually sealed from the outside to greatly reduce damaging environmental elements, such as grinding dust, dirt and high moisture, from affecting the more delicate components.

The left and central area of the units are a wind-tunnel design. With air pulled in from the left side, it is projected across the heat sink elements by on-demand fans. This means the cooling air only has to travel over 1/2 the depth of the unit and only draws in potentially dirty shop air when cooling is needed.

Additional standard features include:

- Capability to store up to 100 programs of your choice

- Driven by a set of specially-made microchips that have an outstanding 20-nanosecond processing speed

- USB port to allow easy download of data and upload of new software

- Built-in interface boards, allowing them to be used manually, semi-automatically, in hard automation or robotically

- Built-in self-diagnostics and basic data collection

- Ability to weld multiple materials with one machine

- LED display of set points for a fast scan of the setup - no need to search through multiple screens

With robust standard features in place, various components may be added or removed to specific machines to achieve the desired process variation. These additions and deletions are then reflected in the final cost of the machine.

Top Differences in Welbee Arc Welders

Welbee M350

The Welbee M350 unit is a DC-CV/CC unit that can GMAW weld steel, stainless steel, aluminum, FCAW, DC scratch start GTAW and SMAW.

The unit, along with all the other Welbees, has excellent short-circuiting transfer with minimal spatter by utilizing our Controlled Bridge Transfer (CBT) waveform technology. The CBT uses our fast circuitry to see a short as it is happening, then alter the power in such a way that the short is cleared more like pulling taffy apart than the explosion of a fuse blowing up.

The M350 is great for thinner parts, parts that have fit up issues and welding operations that do not require pulsed welding. The unit also can run on single or three-phase input power.

Welbee M350L

In addition to all the features noted above for the M350, the Welbee M350L adds Low Spatter mode to the mix. Low Spatter mode takes the DAIHEN CBT to the next level as it creates a very soft short-circuiting arc in the steel and stainless steel (300 & 400) modes. Low Spatter mode is very useful on thin sheet metals and for root passes in pipe welding.

Welbee P400

The biggest seller, the Welbee P400 unit includes all the features and benefits of the M350, plus Pulse and Wave Pulse modes and some additional metals/filler options.

Welbee P500L

The Welbee P500L big boy brings with it all the features and benefits of the M350L and P400 with some extra power. It is equally as adept at welding 1mm aluminum as it is a 1" thick steel plate, thanks to its inverter base and high-speed computer programming.

Welbee W400

The most capable in the line, the Welbee W400 brings AC Pulse and AC Wave Pulse modes to add another dimension to GMAW welding. If arc blow is a consistent problem, AC Pulse or AC Wave Pulse often eliminate this concern.

If you need to weld very thin materials at a decent (GMAW) speed, the AC Pulse may be your ticket. The welding speed and lower amperage on thin materials also have the effect of reducing distortion and warping.

At the other end of the power spectrum, in the AC Pulse mode, it has the ability to control dilution when doing overlay work. In AC Pulse mode, there is more wire deposited at a given amperage than in the DC mode, and with that, a thicker build-up and less dilution are attained. In some cases, this allows a single pass overlay to meet the customer’s requirements, where two passes were required with a DC power source.

All of these features are due to the double inverter in this machine, which allows it to make the polarity switch from negative to positive without extinguishing the arc.

Welbee GTAW (TIG) machine

The line would not be complete without the superb Welbee GTAW (TIG) machine.

The A350P unit is the third generation of GTAW power sources that has a somewhat unique AC + DC hybrid mode. In this mode, the unit switches from AC (for cleaning) to DC (for penetration and speed) and back via adjustable programming.

Most suitable for heavier aluminum work, you can adjust and set the parameters to meet your welding needs. Of course, there are the standard TIG settings like DC, DC Pulse, AC (standard, soft and hard), AC Pulse, EN balance, AC frequency and others. All of these features are due to the double inverter in this machine, which allows it to make the polarity switch from negative to positive without extinguishing the arc.

Be sure to share and save this guide and easy-to-use Welbee model comparison chart.

Ready for a weld demonstration?