When you're running an assembly line, it can seem as though there are a world of choices ahead of you that can impact your overhead and profitability in a number of ways. One area that this happens in is your welding operation. When you need to replace your welding machinery, should you look at new or used welding robots? We've taken a good look at the topic and have developed this cost/benefit analysis to help you decide what's the right choice for your operation.

When you're running an assembly line, it can seem as though there are a world of choices ahead of you that can impact your overhead and profitability in a number of ways. One area that this happens in is your welding operation. When you need to replace your welding machinery, should you look at new or used welding robots? We've taken a good look at the topic and have developed this cost/benefit analysis to help you decide what's the right choice for your operation.

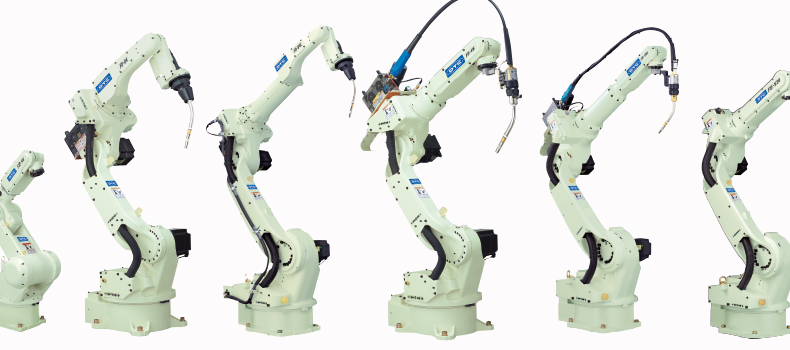

Welding Robots: Benefits of purchasing new vs. used

New Welding Robots

Sure, there's that new-robot smell, but what about beyond the packaging? When you purchase a new welding robot, you receive a guarantee that the machine will perform within specifications for a certain length of time. You're also getting a piece of machinery that has not had any problems in the past, been housed in poor conditions or misused, also not left unrepaired or poorly maintained. Because all these issues can affect the expected useful life span of a welding robot, it can have a big impact on how well it will perform and for how long.

You can also find a robot that meets your exact specifications or order one directly from the manufacturer that meets your needs. Instead of having to make do with what's available in the used robot market, you can get a welding robot that will make your production line faster, safer and work more efficiently for you. All these aspects mean you can run your assembly line with a lower overhead and higher profitability.

Used Welding Robots

But sometimes, even taking all these considerations into account, it's just more affordable to purchase a used welding robot instead of a new one. If your assembly line regularly manufactures average-quality products, you may be able to make do with a used robot. Used welding robots are less expensive, which makes it easier to buy a robot that would still be an upgrade to your previous equipment.

But how do you buy a used robot that will perform as you need? Ask to see all the maintenance and repair logs to verify condition. Have an equipment appraisal performed by an independent certified appraiser. Take a look at where it was used when under production. Ask why the company is getting rid of it. At that point, you at least have a better idea of what you're getting into.

By keeping these benefits and drawbacks in mind, you can choose the right welding robots for your assembly line. Do you need more information on how new welding robots may outperform their used competitors? At OTC Daihen, we've been providing the latest in production welding technology for nearly 100 years. Contact us today to learn how we can help you find the perfect welding robot for your production line.