When you're dealing with quality control issues in your production line, one common area of concern is your welding operation. But what kind of changes do you need to make to improve quality? Are there particular types of welders that can make a difference in your final quality? Absolutely! One common solution is to use a welder with ultra-low spatter features and benefits, but only if it works for your circumstances. Here's a quick look at what situations work well for ultra-low spatter welders.

When you're dealing with quality control issues in your production line, one common area of concern is your welding operation. But what kind of changes do you need to make to improve quality? Are there particular types of welders that can make a difference in your final quality? Absolutely! One common solution is to use a welder with ultra-low spatter features and benefits, but only if it works for your circumstances. Here's a quick look at what situations work well for ultra-low spatter welders.

When to use the CBT Ultra-low spatter welder

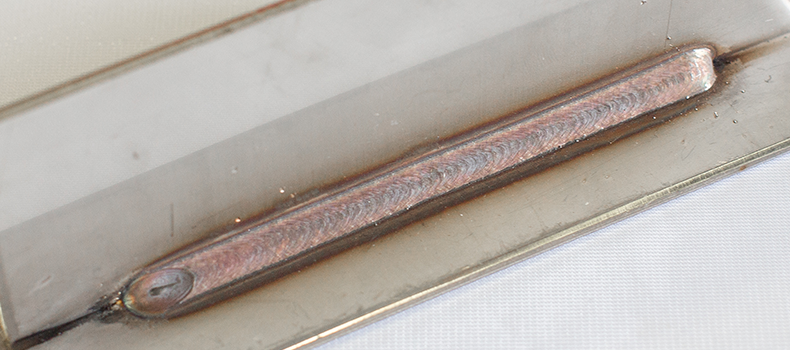

- Thin carbon or stainless steels: Whether you produce body panels, automotive parts or appliances, this type of welder gives you superior performance on thin materials. Instead of dealing with grinding spatter, burn through problems and other quality control issues, you can simply get good quality welds without a lot of cleanup.

- Rough or Poor Fit Up: If your production line tends to have issues with precision and accuracy leading to difficulty with fit up, ultra-low spatter welder also generate low heat input and tends to deal better with this issue than other conventional welder types.

- Out of Position Welds: You need to weld where? It's okay, these welders have you covered and can provide incredible weld puddle control for a better quality weld out of position.

- Helps with Distortion: When you're working with thin material, distortion is a serious problem as the heat causes issues with the material. Low spatter minimize distortion in your welds and in your material.

- Pipe root pass without Reinforcement. If you need to create a better weld on pipe without having to worry about penetration issues, this type of welding can deliver the results you need.

- When your production line material thickness varies from thin to thick, the CBT ultra-low spatter welding process can provide you with a range of features delivering exceptional ultra-low spatter, high quality welds.

- Stainless and Carbon Steel: With the strong focus on stainless and carbon steel in thin material welding, ultra-low spatter welders can deliver exceptional results with beautiful, smooth welds.

By keeping these factors in mind when selecting quality welding equipment for your production line, you can determine whether low spatter or short circuit welders are right for your situation. If you need help or have additional questions about these welders, please feel free to contact us today. At OTC Daihen, we've spent the better part of a century delivering industrial welding innovation.